Applications

• Features

• Construction

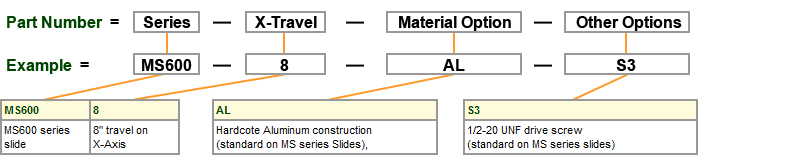

• Standard Options • MS Series Linear Slide Table • How to Order

- Part # and Travels

Manual Positioning Slides

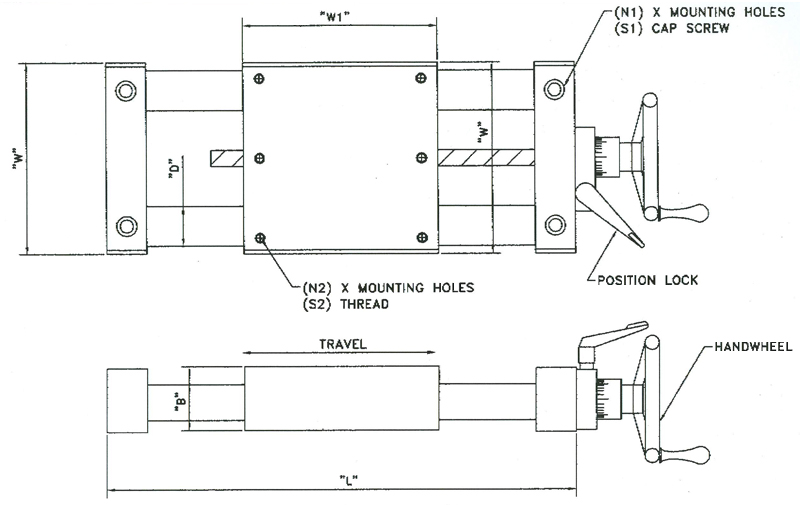

These slides provide smooth repeatable positioning,

of instrumentation, tooling and equipment, via a ridged slide mounting

arrangement. The extremely robust construction, including oversized

guide rails and high PV bearings allow mounting in virtually any

position. (Horizontal, vertical, side mount and body mount.). Cantilevered

and end supported gantry type mounting is also possible with little

or no concern for deflections. Standard options include Hand-wheel

choices, position locks, Engraved dials, and digital position indicators.Use

GENERIC SLIDES – Quality Manual positioning slides as an effective

and cost efficient solution to your instrumentation, processing,

manufacturing and automation system needs.

Applications

Include:

Applications

Include:

- Optics adjustments

- Laser positioning

- Positioning label dispensing equipment

- Positioning marking equipment

- Non-destructive testing

- Fixturing tooling and part locating nests

- Part scanning

- Automatic screw drivers

- Insertion equipment

- Fluid dispensing equipment

- Water-jet cutting

- Routing, drilling and milling spindles and

tooling

- Automation devices

Features:

Features:

- Travels to 216" inches

- Table widths to 1.75" to 24"

- Delicate to course adjustments

- Heavy payloads

- Smooth motion

- X-Y Tables

- X-Y –Z Multi-Axis units

Construction:

Construction:

- Position lock

- Rolled thread drive screw

- Adjustable backlash drive screw nut

- Heavy section HardCote™

- Radically oversized guide rails

- High PV composite bearings

Standard

Options:

Standard

Options:

- Engraved position dials

- Digital positional indicators

- X-Y Tables

- X-Y –Z Multi-Axis units

- Longer Travel Units

- Custom Table Sizes

- Custom Mounting Holes

^ Go to Top ^