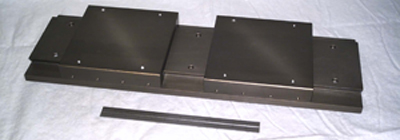

| These self-centering slides provide

dual platforms for smooth repeatable positioning, of instrumentation,

tooling, and equipment via a rigid slide mounting arrangement.

A turn of the hand-wheel advances the slide tables toward,

or away from the slide center. As an option the dual carriage

slide can be provided with one driven table and one free sliding

table. This arrangement has been proven to be useful in supporting

large work pieces.

The extremely robust construction, includes oversized guide

rails and high PV bearings allow mounting in an extended horizontal

position. The slides also allow for a vertical mounted slide

to be attached providing movement in the “X” and Z” axis’s.

Standard options include Hand-wheel choices, position locks,

Engraved dials, and digital position indicators. Use Generic

Slides – Quality manufactured Dual Carriage Slides, as an

effective and cost efficient solution to your instrumentation,

manufacturing and Automation systems needs. |