BS Series 45 Ball Slides (Dimensions

& Drawings) • BST Series

Ball Slides(Dimensions

& Drawings)

BS Series Ball

Slides

Model

No. : PS45

PNEUMATIC SLIDES

Air Cylinder Slides provide a conveniently packaged

solution for lift, transfer, and alignment hole provide

mounting flexibility. Standard units can be combined for

multi-axis motions

|

|

|

Model No. : MS45 -

MICROMETER SLIDES

Precision micrometer adjustment allows precise and repeatable

positioning of gaging, instrumentation, and optics. These

slides are also used for flexible fixturing and adjustable

mounting of equipment and tooling. The slide is also available

in a side mounted drive configuration. |

|

|

Model No. : SS45 -

LEAD SCREW SLIDES

Standard and precision lead screw slides with optional

Stepper or Servo motor, drives and controllers. These

actuators can be combined to create the application specific,

programmable motion system best suited for your needs. |

|

|

|

|

| Model

No: BS45 Precision

Ball Slide |

Model

No: XY45 X-Y

Slide Assembly

|

Model

No: XZ45 X-Z

Slide Assembly |

|

|

|

|

Model No:

XZS45 X-Z

Slide Assembly

Side Mount Configuration |

Model

No: XYZS45 X-Y-Z

Slide Assembly Side Mount Configuration |

Model

No: XYZ45 X-Y-Z

Slide Assembly |

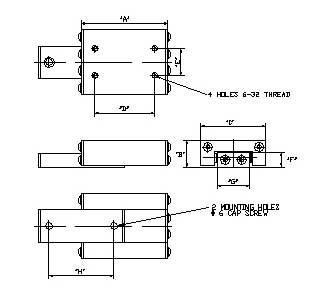

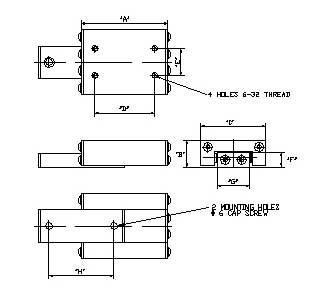

BS

Series Ball Slides (Dimensions & Drawings)

Drawings and Dimensions BS

45 Series

|

~

Custom Units Available ~ |

(F)

|

Part

# |

Travel |

Payload |

A |

B |

C |

D |

#

of Mtg. Holes |

|

BS45-1 |

1 |

28 lbs. |

2.00 |

1.000 |

.500 |

.50 |

2 |

|

BS45-2 |

2 |

40 lbs. |

3.00 |

1.000 |

1.000 |

1.00 |

2 |

|

BS45-4 |

3 |

60 lbs. |

5.00 |

1.000 |

1.000 |

2.00 |

4 |

|

BS45-6 |

6 |

80 lbs. |

7.00 |

1.000 |

1.000 |

3.00 |

6 |

* Travels

shown are minimum travels. ** Payload value is for load applied

at center of tabletop. (F = center of load.)

|

Dovetail

Nuts for use with BS45 Series Ball Slides |

|

Part # |

Thread |

|

DN - .13 |

# 6-32 |

|

DN - 4 M |

4 |

| |

|

X-Z Bracket

for use with BS45 Series Ball Slides

|

|

Part # |

Thread |

|

XZBR3 |

# 6-32 / M4 |

|

XZBR4 |

#6-32 / M4 |

BST Series Ball

Slides

|

Part

# |

Travel

|

Payload

|

A

|

B

|

C

|

D

|

E

|

F

|

G

|

H

|

|

BST100-.5 |

.5

|

5

|

1.31

|

.5

|

1.00

|

1.250

|

.437

|

.34

|

.38

|

.875

|

|

BST100-.75 |

.75

|

10

|

1.56

|

.5

|

1.00

|

1.250

|

.437

|

.34

|

.38

|

1.125

|

|

BST100-1.5

|

1.5

|

15

|

2.56

|

.5

|

1.00

|

2.250

|

.437

|

.34

|

.38

|

2.125

|

|

BST100-2 |

2

|

25

|

3.56

|

.5

|

1.00

|

3.250

|

.437

|

.34

|

.38

|

3.125

|

|

BST100-3 |

3

|

30

|

4.56

|

.5

|

1.00

|

4.000

|

.437

|

.34

|

.38

|

3.250

|

|

BST100-4 |

4

|

35

|

6.00

|

.5

|

1.00

|

5.000

|

.437

|

.34

|

.38

|

4.000

|

|

BST150-1 |

1

|

15

|

2.00

|

.62

|

1.5

|

1.375

|

.625

|

.34

|

.75

|

1.500

|

|

BST150-2 |

2

|

20

|

3.00

|

.62

|

1.5

|

2.375

|

.625

|

.34

|

.75

|

2.500

|

|

BST150-3 |

3

|

25

|

4.00

|

.62

|

1.5

|

3.375

|

.625

|

.34

|

.75

|

3.500

|

|

BST150-4 |

4

|

30

|

5.00

|

.62

|

1.5

|

5.375

|

.625

|

.34

|

.75

|

4.000

|

|

BST150-6 |

6

|

35

|

6.00

|

.62

|

1.5

|

7.375

|

.625

|

.34

|

.75

|

5.000

|

|

BST175-1 |

1

|

20

|

2.00

|

.75

|

1.75

|

1.375

|

.875

|

.400

|

.875

|

1.625

|

|

BST175-2 |

2

|

30

|

3.25

|

.75

|

1.75

|

2.625

|

.875

|

.400

|

.875

|

2.750

|

|

BST175-3 |

3

|

40

|

4.00

|

.75

|

1.75

|

3.375

|

.875

|

.400

|

.875

|

3.500

|

|

BST175-4 |

4

|

50

|

6.00

|

.75

|

1.75

|

5.500

|

.875

|

.400

|

.875

|

4.00

|

|

BST175-6 |

6

|

65

|

8.00

|

.75

|

1.75

|

7.5

|

.875

|

.400

|

.875

|

5.00

|